TSA Tung Shin Industrial Co., Ltd. (Vietnam) In response to customer demand for high-quality aluminum casting rods, TSA has continuously optimized and expanded its production capacity and lines in recent years. To produce cleaner and higher-quality aluminum casting rods, the aluminum melt is made from high-purity aluminum ingots. The melting process uses an “electromagnetic stirring system” for mixing, along with an advanced online degassing system and dual-layer ceramic filter plates to effectively remove hydrogen atoms and inclusions from the melt. Combined with an “online hydrogen measurement device” for real-time monitoring of hydrogen content, sufficient homogenization treatment is employed to eliminate element segregation, resulting in stable production of high-quality aluminum alloy casting rods. Production Capacity: 30,000 tons/year.

Equipment

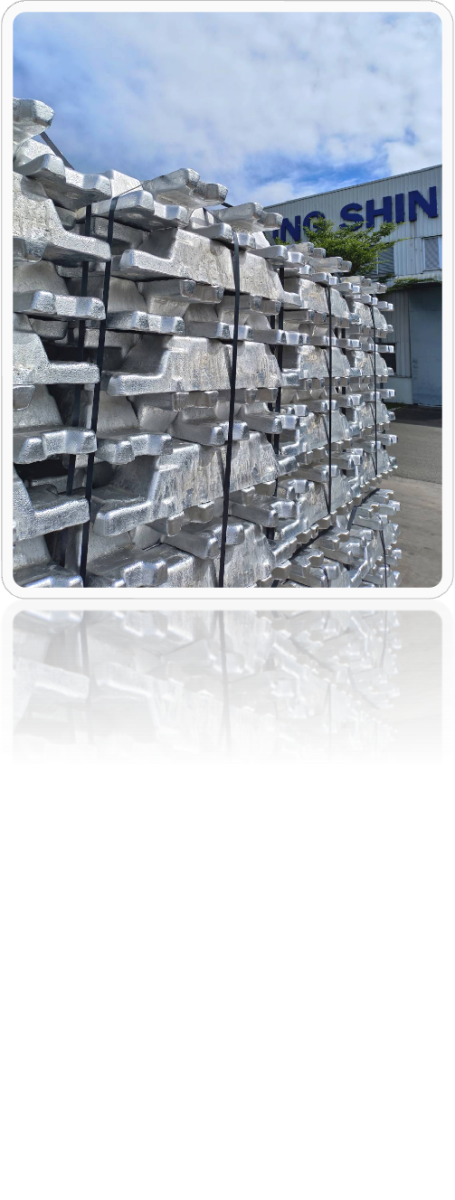

- Supply of high-purity electrolytic aluminum ingots and green energy aluminum ingots

- Electronic stirring equipment

- Digital grain refining feeding machine

- Online degassing system

- Programmable heated filter box with dual ceramic filter plates

- Casting equipment

- Programmable homogenizing furnace equipment

Equipment Introduction

- High-Purity Electrolytic Aluminum Ingots and Green Energy Aluminum Ingots Supply

The raw materials used by our company (electrolytic aluminum ingots, green energy aluminum ingots, etc.) are sourced from internationally renowned suppliers such as Tomago and Bintulu. This ensures quality and provides the advantage of reducing the carbon footprint of our products.

- Electromagnetic Stirring Equipment

This equipment allows for rapid stirring of the molten aluminum, achieving uniform temperature and composition throughout the melt.

- Digital Grain Refinement Feeding Machine

During the casting process, the machine adds appropriate grain refiners at a stable feeding rate, meeting the customized grain refinement needs for aluminum extrusion rods.

- Online Hydrogen Removal System

This system features high-speed Ar gas hydrogen removal equipment manufactured by PYROTEK, effectively reducing hydrogen content within the metal.

- Filtration Box with Programmable Heating and Dual Ceramic Filter Plates

Utilizing PYROTEK’s patented 20” dual ceramic filter plate system and LIG programmable preheating cover, this equipment can be configured for two levels of filtration (30, 40 PPI / 50, 70 PPI) based on customer cleanliness requirements, ensuring the highest quality of the final product.

- Casting Equipment

The casting of aluminum rods employs Hot Top casting equipment, combined with an online FIM (degassing, refining) system, dual ceramic filter plate system, and digital grain refinement feeding machine to achieve optimal production of aluminum rods.

- Programmable Homogenization Furnace Equipment

TSA has installed three 20-ton cart-type programmable temperature-controlled homogenization furnaces and one water shower. These can meet uniform temperature requirements and allow for controlled heating, holding, and cooling rates based on different alloys, ensuring the aluminum rods achieve the best homogenization treatment effect.